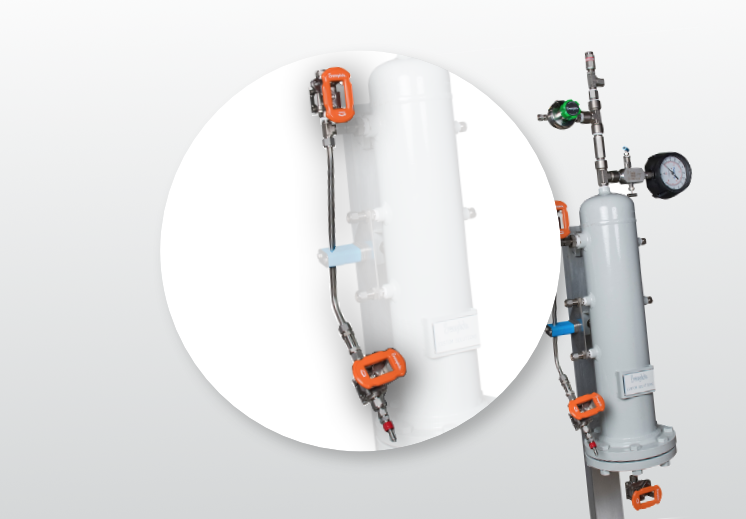

Seal Pot Fill Tube

Safer Seal Pot Maintenance

During operation of a barrier or buffer fluid system it is common to have seal leakage on the outboard and or the inboard side of the seal depending on which plan is in operation. That means that process leaking through the seal is collected by the barrier fluid system and therefore is contaminated. It also means that the barrier fluid level will diminish over time and require filling of the seal reservoir.

Fill Seal Pots Without Risking Exposure

Swagelok seal pot fill tubes enable you to fill seal pots safely while they remain in operation. The block valves, and check valve ensure that operators are safe from any contaminants or hydrocarbons that will be mixed in with the barrier fluids.

Safe for Pressurized Systems

If the system is pressurized, seal pot fill tubes enable technicians to fill the reservoirs using “fill carts” that overcome the pressurized barrier systems.

On pressurized systems (such as API Plan 53A), without some sort of valving on the fill port to block off the nitrogen, the pump must be brought down to fill the reservoir. Using Swagelok fill tubes allow for standardization of the filling process which will help to reduce potential technician exposure and increase uptime.

Download the Seal Pot Fill Tube Quick Look for More Information and to Share with Your Team